Choosing the right takeaway box material has become a critical decision for restaurants, cafes, and food service businesses worldwide. As consumer awareness about environmental impact grows and regulations around single-use plastics tighten, food service operators must carefully evaluate their packaging options. The debate between plastic and paper takeaway box material extends beyond simple cost considerations, encompassing factors like durability, environmental impact, food safety, and customer preferences. Understanding these materials' properties helps businesses make informed decisions that align with their sustainability goals while maintaining operational efficiency.

The food packaging industry has witnessed significant transformation in recent years, driven by changing consumer expectations and environmental regulations. Traditional plastic containers, once the standard choice for takeaway applications, now face scrutiny for their environmental footprint. Meanwhile, paper-based alternatives have evolved dramatically, offering improved performance characteristics that challenge conventional assumptions about takeaway box material selection. This evolution reflects broader shifts in the food service industry toward more sustainable practices without compromising food quality or customer satisfaction.

Environmental Impact Comparison

Carbon Footprint Analysis

When evaluating takeaway box material from an environmental perspective, carbon footprint represents a crucial metric. Paper-based containers typically demonstrate lower carbon emissions during production compared to plastic alternatives. The manufacturing process for paper containers relies primarily on renewable wood fiber, which acts as a carbon sink during tree growth. Additionally, paper production facilities increasingly utilize renewable energy sources, further reducing their environmental impact. The transportation footprint also favors paper containers due to their lighter weight and efficient stacking capabilities.

Plastic takeaway containers, while requiring more energy-intensive production processes, offer certain environmental advantages in specific contexts. Their durability means longer service life in reusable applications, potentially offsetting initial production emissions. However, the fossil fuel dependency in plastic manufacturing creates inherent carbon intensity that paper alternatives typically avoid. Modern recycling programs can help mitigate plastic's environmental impact, though recycling rates for food-contaminated containers remain challenging across many markets.

Biodegradability and Waste Management

The end-of-life characteristics of takeaway box material significantly influence environmental impact assessments. Paper containers excel in biodegradability, breaking down naturally in composting facilities within weeks under proper conditions. This biodegradation process returns organic matter to soil systems, supporting circular economy principles. Many paper containers now feature compostable coatings that maintain food safety standards while preserving biodegradability, addressing previous concerns about moisture barriers.

Plastic containers face substantial challenges in waste management systems. Traditional plastic takeaway boxes can persist in landfills for hundreds of years, contributing to long-term environmental burden. Even recyclable plastics often end up in general waste streams due to food contamination or inadequate sorting systems. However, emerging biodegradable plastic formulations offer promising alternatives, though these materials require specific composting conditions not universally available in waste management infrastructure.

Performance and Functionality

Durability and Strength Characteristics

Performance evaluation of takeaway box material must consider real-world usage scenarios that food service operations encounter daily. Plastic containers traditionally offered superior durability, maintaining structural integrity under various temperature and moisture conditions. Their resistance to puncturing and tearing made them preferred choices for foods with sharp components or heavy sauces. This durability translated to reduced product loss and fewer customer complaints about packaging failures during transport.

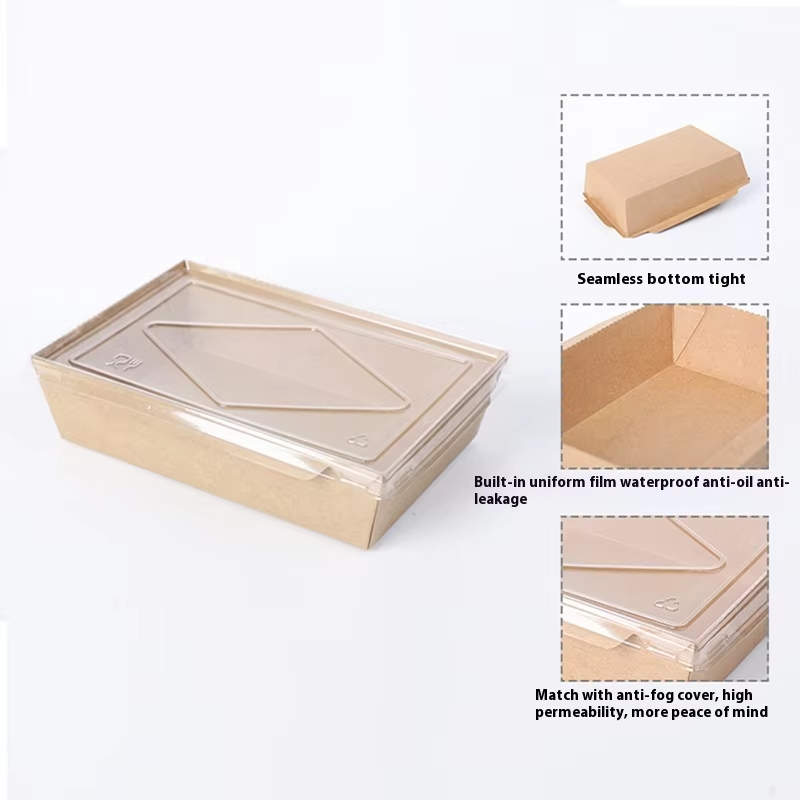

Modern paper takeaway containers have significantly improved their performance characteristics through advanced engineering and coating technologies. High-quality paper containers now demonstrate impressive strength-to-weight ratios, handling typical food service loads without compromising structural integrity. Specialized folding techniques and reinforcement designs enhance corner strength and bottom stability, addressing traditional weakness points in paper packaging. These improvements have narrowed the performance gap between plastic and paper alternatives considerably.

Temperature and Moisture Resistance

Temperature performance represents a critical factor in takeaway box material selection, particularly for hot food applications. Plastic containers generally maintain dimensional stability across wide temperature ranges, preventing warping or structural failure when exposed to hot foods. Their inherent moisture barrier properties protect food quality while preventing container degradation from steam or liquid contact. This reliability made plastic the traditional choice for soup containers, hot entrees, and foods with high moisture content.

Contemporary paper containers incorporate sophisticated barrier technologies that rival plastic performance in many applications. Advanced coating systems provide excellent grease resistance while maintaining paper's natural breathability for optimal food texture preservation. Heat-resistant designs prevent scorching or weakening when exposed to hot foods, while moisture barriers protect container integrity throughout the service cycle. These technological advances enable takeaway box material selection based on environmental priorities without sacrificing functionality.

Cost Considerations and Economic Factors

Initial Purchase Price Analysis

Economic factors play a decisive role in takeaway box material selection for most food service operations. Plastic containers historically offered lower unit costs due to efficient manufacturing processes and economies of scale. High-volume production facilities could produce plastic containers at costs significantly below paper alternatives, making them attractive for price-sensitive operations. Additionally, plastic's durability reduced replacement costs associated with packaging failures, providing additional economic benefits beyond initial purchase prices.

Paper container pricing has become increasingly competitive as production volumes increase and manufacturing efficiency improves. While premium paper options may carry higher unit costs than basic plastic alternatives, the price differential continues narrowing across many product categories. Bulk purchasing agreements and long-term supplier relationships can further reduce paper container costs, making them economically viable for operations prioritizing sustainability. The total cost equation must also consider potential regulatory compliance costs associated with plastic packaging restrictions.

Long-term Economic Impact

Comprehensive economic analysis of takeaway box material extends beyond immediate purchase prices to encompass broader business implications. Restaurants choosing environmentally responsible packaging often experience enhanced brand reputation and customer loyalty, potentially offsetting higher material costs through increased sales. Marketing advantages associated with sustainable packaging choices can drive customer acquisition and retention, particularly among environmentally conscious demographics that typically demonstrate higher spending patterns.

Regulatory trends suggest increasing costs for plastic packaging through taxes, fees, or disposal requirements across many jurisdictions. Forward-thinking businesses often find economic advantage in proactively transitioning to compliant packaging materials before mandatory requirements take effect. This strategic approach avoids rushed transitions during regulatory implementation phases, when alternative material availability may be limited and prices elevated due to sudden demand increases.

Food Safety and Hygiene Standards

Contamination Prevention

Food safety considerations fundamentally influence takeaway box material selection across all food service operations. Plastic containers offer inherent advantages in contamination prevention due to their non-porous surfaces and resistance to moisture penetration. These characteristics prevent bacterial growth and cross-contamination risks, making plastic suitable for extended storage periods and challenging environmental conditions. The smooth surfaces of plastic containers also facilitate thorough cleaning in reusable applications, supporting food safety protocols in commercial kitchens.

Paper-based takeaway containers have achieved significant improvements in food safety performance through advanced barrier technologies and antimicrobial treatments. Modern paper containers feature specialized coatings that prevent moisture and grease absorption, eliminating traditional contamination pathways. These barriers maintain food quality while preventing container degradation that could compromise hygiene standards. Rigorous testing and certification processes ensure paper containers meet stringent food contact safety requirements across international markets.

Chemical Migration and Food Contact Safety

Chemical migration concerns influence takeaway box material evaluation, particularly for applications involving acidic foods or extended contact periods. Certain plastic formulations may release trace chemicals into food products under specific conditions, raising concerns about long-term health implications. Regulatory agencies continue monitoring and updating safety standards for plastic food contact materials, requiring ongoing compliance verification from manufacturers and food service operators.

Paper containers generally demonstrate excellent chemical migration profiles due to their natural composition and carefully selected coating materials. The wood fiber base provides an inert barrier that prevents unwanted chemical interactions with food products. However, paper container safety depends heavily on coating quality and manufacturing processes, requiring careful supplier selection and quality assurance protocols. Certified compostable coatings offer additional safety assurance while maintaining environmental benefits that distinguish paper from plastic alternatives.

Consumer Preferences and Market Trends

Environmental Consciousness Impact

Consumer attitudes toward takeaway box material have shifted dramatically as environmental awareness increases across global markets. Surveys consistently demonstrate growing preference for sustainable packaging options, with many consumers willing to pay premium prices for environmentally responsible alternatives. This trend particularly influences younger demographics and urban populations, who often represent high-value customer segments for food service operations. The visual distinction between paper and plastic packaging allows consumers to immediately identify businesses aligned with their environmental values.

Social media and digital marketing amplify the impact of packaging choices on brand perception and customer engagement. Restaurants featuring sustainable takeaway box material often receive positive social media attention and user-generated content that provides valuable marketing exposure. Conversely, businesses perceived as environmentally irresponsible may face criticism and boycotts that significantly impact sales and reputation. This dynamic creates strong economic incentives for sustainable packaging adoption beyond regulatory compliance requirements.

Regional Preferences and Cultural Factors

Geographic and cultural variations significantly influence takeaway box material preferences across different markets. European consumers generally demonstrate stronger preferences for paper-based packaging, supported by comprehensive recycling infrastructure and environmental regulations. Asian markets show more varied preferences, often balancing environmental concerns with practical considerations like food presentation and functionality. Understanding these regional differences enables food service chains to optimize packaging strategies for local market conditions while maintaining consistent sustainability commitments.

Cultural associations with different materials also influence consumer perceptions and purchasing decisions. Paper packaging often conveys premium, artisanal, or health-conscious brand positioning that resonates with specific market segments. This perception can justify higher menu prices and attract customers seeking authentic or responsible dining experiences. Marketing strategies that effectively communicate the environmental and quality benefits of sustainable takeaway box material selection can create competitive advantages in increasingly crowded food service markets.

Regulatory Landscape and Compliance

Current Legislation and Requirements

Regulatory frameworks surrounding takeaway box material continue evolving rapidly across international markets, creating complex compliance requirements for food service operations. Many jurisdictions have implemented or announced bans on specific plastic packaging types, requiring businesses to transition to approved alternatives within defined timeframes. These regulations often specify acceptable material types, recyclability requirements, and disposal methods that directly impact packaging selection decisions. Staying current with regulatory developments requires ongoing monitoring and strategic planning to ensure compliance continuity.

Certification requirements for sustainable packaging materials have become increasingly rigorous, demanding comprehensive documentation of environmental claims and performance characteristics. Paper containers must demonstrate compliance with composability standards, recycled content requirements, and forest management certifications to qualify for regulatory approval in many markets. These certification processes provide assurance to businesses and consumers while creating barriers to entry that favor established manufacturers with proven track records in sustainable packaging development.

Future Regulatory Trends

Anticipated regulatory developments suggest continued expansion of plastic packaging restrictions and increased support for sustainable alternatives. Extended producer responsibility programs increasingly hold packaging manufacturers accountable for end-of-life costs, creating economic incentives for sustainable takeaway box material development. Carbon pricing mechanisms and environmental taxes may further shift economic calculations in favor of paper-based packaging solutions that demonstrate lower environmental impact across their lifecycle.

International harmonization of packaging standards could simplify compliance requirements for multinational food service operations while accelerating adoption of best practices across different markets. These developments favor packaging materials with proven sustainability credentials and broad regulatory acceptance, positioning paper containers advantageously for future market expansion. Proactive compliance with emerging standards can provide competitive advantages and reduce transition costs as regulations become mandatory requirements.

FAQ

Which takeaway box material offers better food preservation

Food preservation performance depends on specific application requirements and food types. Plastic containers generally provide superior moisture barriers and extended shelf life for refrigerated items, while paper containers excel at maintaining food texture through controlled breathability. Modern paper containers with advanced coatings offer comparable preservation performance for most applications while providing environmental benefits. The choice should consider food type, storage conditions, and service duration to optimize preservation effectiveness.

How do costs compare between plastic and paper takeaway containers

Initial purchase costs for paper containers typically run 10-30% higher than comparable plastic options, though this gap continues narrowing as production scales increase. However, comprehensive cost analysis should include potential regulatory compliance expenses, waste disposal fees, and marketing advantages associated with sustainable packaging choices. Many businesses find that customer preference for environmental responsibility and brand enhancement benefits offset higher material costs through increased sales and customer loyalty.

What environmental certifications should I look for in takeaway box materials

Key certifications for sustainable takeaway box material include FSC (Forest Stewardship Council) certification for responsible forestry, BPI (Biodegradable Products Institute) compostability certification, and ASTM D6400 or EN 13432 standards for industrial composting compatibility. These certifications ensure materials meet rigorous environmental standards and perform as claimed in waste management systems. Additionally, look for recycled content certifications and carbon footprint assessments that provide comprehensive sustainability verification.

Can paper takeaway containers handle hot and greasy foods effectively

Modern paper takeaway containers feature sophisticated barrier coatings that effectively handle hot, greasy, and acidic foods without compromising structural integrity or food safety. These coatings prevent grease absorption and maintain container strength under challenging conditions while preserving compostability characteristics. Performance testing demonstrates that high-quality paper containers match or exceed plastic alternatives in most food service applications, making them viable options for diverse menu items including soups, fried foods, and saucy dishes.